We leave a small glossary where we go over some of the technical terms that appear in our articles in case they can help you.

Accuracy

It is the measurement tolerance of an instrument, defined as the interval where it is permissible to place the magnitude of the measurement. Defines the limits of errors made when the instrument is used in normal conditions of service.

ADC

Analog / digital converter. Electronic device or circuit that converts an analog input into a digital signal.

Adjustment of a measuring instrument

It is the necessary operation to bring a measuring instrument to an operating state suitable for its use.

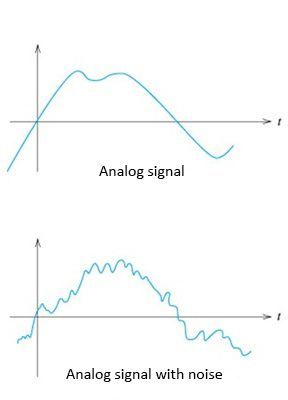

Analog signal

The analog signal is any signal that has a continuous variation over time.

The analog signals come from a physical magnitude and predominate in our environment (variations of temperature, pressure, speed, distance, sound, etc.). These signals can be transformed into electrical signals, through the appropriate transducer, for their treatment.

A sine wave is an analog signal of a single frequency.

The great disadvantage with regard to digital signals is the noise in the analog signals: any variation in the information is difficult to recover, and this loss greatly affects the correct operation and performance of the analog device.

Cable gland

Device that allows the introduction of one or more cables in an enclosure in order to maintain the corresponding mode of protection.

Calibration

Set of operations that establish, under specific conditions, the relationship between the values of the magnitudes indicated by an instrument or measuring system and the corresponding values of that magnitude made by patterns.

Category (explosive atmospheres)

It classifies a device depending on its level of protection within a potentially explosive atmosphere.

Depending on the level of safety, two categories for group I (M1 and M2) and three categories for group II (1, 2 and 3) are established:

Category M1 and 1 comprises designed equipment which can ensure a very high level of protection.

Category M2 and 2 comprises designed equipment that can ensure a high level of protection.

Category 3 comprises equipment designed to ensure a normal level of protection.

Coil or inductor

Passive two-terminal electrical component that stores electrical energy in a magnetic field when electric current is flowing through it. It is made by winding a conductive wire over a core of ferromagnetic material.

The operation of the coil implies that it will react against changes in current by dropping voltage in the polarity necessary to oppose the change.

The induction coil was invented by the Irish scientist and Catholic priest Nicolas Callan in 1836.

Cut off (flowmeters)

It is the flow rate below which the meter will indicate or will give its output as zero value. It is a way of avoiding that small errors near zero rebound in totalized quantities.

DAC

Digital / analog converter. Electronic device or circuit that converts a digital input into an analog signal.

Dead zone

It is the range of values of the measured variable that does not vary the indication or the output signal of the instrument, that is to say, that does not produce its answer.

Error (instrumentation)

It is the algebraic difference between the measured value and the actual value of the measured variable.

Explosive atmosphere

Explosive atmosphere means any mixture of dangerous substances with air, under atmospheric conditions, in the form of gases, vapors, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

Frameproof enclosure (explosive atmospheres)

Enclosure in which the parts which can ignite an explosive atmosphere are enclosed and which withstand the pressure developed during an internal explosion of an explosive mixture and which prevents the transmission of the explosion to the atmosphere of explosive gas surrounding the enclosure.

Groups (explosive atmospheres)

They classify the location where electrical equipment is intended to be used in a potentially explosive atmosphere.

In the classification there are three groups:

Group I of equipment intended for use in mines with risk of firedamp or other flammable gases.

Group II of equipment intended for surface use with presence of gas, liquids or vapors.

Group III of equipment intended for use in surfaces with presence of explosive dust atmosphere.

Intrinsic safety (explosive atmospheres)

Mode of protection based on the limitation of the energy in a device and on the interconnection cables exposed to an explosive atmosphere at a level below that which may be caused by spark ignition or by thermal effect.

Magnetic coupling

Physical phenomenon in which by effect and action of a pair or set of permanent magnets there is a follow-up between both that is used for different functions such as indication of flow or level, action on switches or transmitters, etc.

Magnetic filter

Accesory used to capture the magnetic particles present in suspension in a fluid. This prevents them from interfering with the correct operation of a flowmeter based on magnetic coupling.

Measurant

Parameter being measured.

Measurement

Set of operations that aim to determine the value of a magnitude.

Measurement uncertainty

It is a parameter associated to the result of a measurement, which characterizes the dispersion of the values that are attributed to the true value of the measured quantity.

Measuring instrument

Equipment, apparatus or machine that performs the reading of a property (or characteristic) of a random variable; processes it, translates it and makes it understandable to the analyst in charge of the measurement.

Measuring pattern

It is a materialized measure, a measuring instrument, a reference material or a measurement system for defining, performing, preserving or reproducing a unit or one or more values of a magnitude, in order to serve as a reference.

Measuring range

Spectrum or set of values between the upper and lower limits of the measuring capacity of an instrument.

Metrology

It is the science of measurement

NAMUR device

Proximity sensor with 2-wire output, which is normally used in areas of explosive atmospheres. Unlike the conventional ones, it is a sensor without amplification that due to the low voltage and current levels can be certified as intrinsic safety (Exi) and therefore it can be located in a hazardous area with explosion risk. It is connected to a zener barrier and the amplifier located in the safe area.

When an object approaches a NAMUR sensor, it varies its internal resistance, causing an increase in current consumption. The external amplifier is responsible for evaluating this change and converting it into a switching signal.

NAMUR (IEC 60947-5-6)

International standard that applies to proximity sensors connected for operation by a two-wire connecting cable to the control input of a switching amplifier. The origin of the name NAMUR comes from the German organism Normenausschuß für Meß und Regelungstechnik.

Non-magnetic (material)

Material that does not have a magnetic field and cannot be converted into a magnet.

Paramagnetic (material)

Material with magnetic properties and with a tendency to become magnetized.

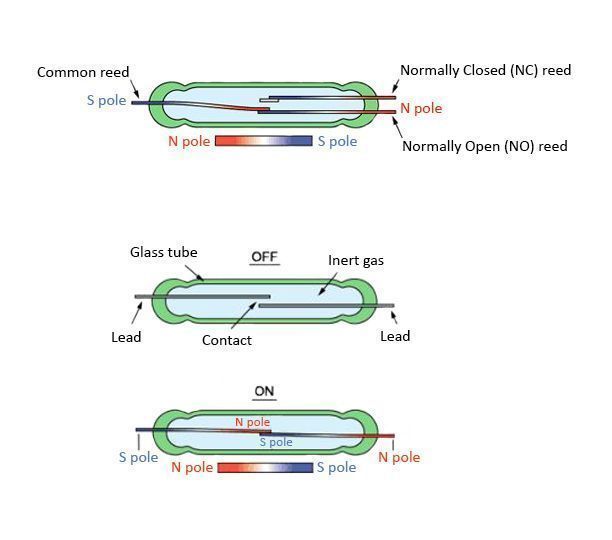

Reed switch

A reed switch is an electrical switch operated by an applied magnetic field.

The contacts may be normally open, closing when a magnetic field is present, or normally closed and opening when a magnetic field is applied.

It was invented by W. B. Ellwood in 1936 while working for Bell Laboratories.

The reed switch consists of a pair of vacuum-enclosed contacts inside a glass tube.

Since the contacts are sealed, the reed switches are used in places with explosive atmospheres, where other switches are considered dangerous. This is because the spark that occurs when opening or closing their contacts is contained inside the glass tube.

Repeatibility

It is the reproduction capacity of the output signal of an instrument by repeatedly measuring identical values of the variable under the same operating conditions.

Scale of a measuring instrument

An ordered set of marks with all associated numeration, which is part of an indicating device of a measuring instrument.

Simple apparatus (explosive atmospheres)

It is an electrical component or set of components of simple construction that has well defined electrical parameters and that is compatible with the intrinsic safety of the circuit in which it is used.

If it is a source of energy, it must not generate or store more than 1,5 V, 100 mA and 25 mW.

These components do not need to be marked, but must comply with all requirements of EN 60079-11.

Switch

Device, adjustable or not, interposed in an electrical circuit in such a way that it can interrupt the passage of the current. It is used to detect a predetermined position of a certain variable and emit a signal for the user’s knowledge.

Temperature class (explosive atmospheres)

Equipment may not have hot spots on its external surface that may cause auto-ignition. Different substances may combust at different temperatures. The lower the combustion temperatura is, the more dangerous the substance is. Consequently, each device, used in an explosive environment, is classified according to the maximal surface temperature it generates.

There are 6 classes of temperature, from T1 to T6:

The maximum surface temperature of the material should always be well below the auto-ignition temperature of the dusts or gases present.

Traceability

Property of the result of a measurement that allows it to be related to specific references, usually national or international standards, through an uninterrupted chain of comparisons, all with established uncertainties.

Water hammer

Harmful effect mainly for variable area flowmeters, produced by a sudden increase in pressure and / or flow rate in said meter.

This increase causes the quick elevation of internal float, causing it to move at high velocity towards the top of the measuring tube, hitting and damaging it, or damaging the internal components of the meter.

It is common in applications where solenoid valves or quick release valves are used.

Zones (explosive atmospheres)

The substance present in the area determines a level of danger based on the frequency of the occurrence of the explosive atmosphere.

For group II (surface gas):

Zone 0 if gas mixtures are present continuously or frequently.

Zone 1 if gas mixtures are likely to occur in normal operation occasionally.

Zone 2 if gas mixtures are not likely to occur in normal operation but, if it does occur, will persist for a short period only.

For group III (surface dusts):

Zone 20 if combustible dust is present continuously or frequently.

Zone 21 if combustible dust is likely to occur in normal operation occasionally.

Zone 22 if combustible dust is not likely to occur in normal operation but, if it does occur, will persist for a short period only.