Today we interview Esteve Cusidó, the responsible person for R&D in Tecfluid. The R&D department is one of our most important departments since it represents the heart of the company’s knowledge when developing or updating a product, being able to carry out a quality after-sales service or customizing a product.

Well Esteve, I think that through this interview you can give us all a better perspective of the work that usually do a Research and Development department within a company. How long have you been working as the head of Tecfluid’s R&D department?

EC – I have been as head of the department since 2000 but I joined the electronics department of the company in 1994. At that time, it was jointly part of R&D and another part of manufacturing. At the beginning, my main dedication was to design electronics applicable to both our flowmeters and level meters and thus update all instruments by implementing microprocessors for the first time that were not available by then.

R&D as such has always existed in Tecfluid. Since their beginnings in 1974, research and design development functions have been carried out, but it was not until 2000 when Tecfluid built a second warehouse and reorganized the company’s organizational chart. The electronics R&D department was separated from the electronics manufacturing and a unique R&D department with two sub departments, electronics and mechanics, was created. That is when I assume the responsibility of this global department.

And how were the beginnings since it was decided to create the R&D department within the organizational chart?

EC – It was obvious I think. As the company grew, the management of the company saw that research part should be separated from the manufacturing part. At the end, the department was created so that the people who were dedicated to research were together and separated from the rest of departments.

R&D department – Electronics

R&D department – Mechanics

Tell us about your day-to-day at work is like. What is your job here?

EC – The mission of R&D in Tecfluid encompasses three main points: Create new products, update existing ones and adapt some to customized solutions to fulfill customer’s needs.

Personally, my day-to-day consists of coordinating that these 3 points are carried out properly. This requires interaction with other departments and the management of the company.

There are difficult days when I am in front of a computer, concentrated on a very technical part of a design, for example, special programming or looking for the best solution for something.

As head of the department, I have many days of meetings with other departments, design follow-up, planning, technical documentation, certifications, etc.

How many people make up the department and what is their role?

EC – In the department, we are 6 people of which 3 are dedicated to the most mechanical part and the other 3 to the most electronic part. In any case, this differentiation, with the years, is becoming more and more diffuse and there is a more complete teamwork.

A few years ago, the designs were more mechanical and today any design, both flow and level, involves an important electronic part that is what makes the entire measurement function together with some mechanical element that helps.

The profile of the staff of the department is a technical or senior engineer. Sometimes we give the feeling of being something “geek”, but the reality is that, although everyone here is usually very involved in the work we are also normal, open people.

Has the way of working changed from the beginning of the creation of R&D in Tecfluid to the present? How?

EC – It has changed a lot. On the one hand, forced external effects such as changes in regulations and directives, as well as market demands, require a continuous adaptation that affects the design process.

On the other hand, the design mechanisms have changed substantially, especially in the electronic part with specialized software for the design itself, and for tests and trials. The change in manufacturing processes also influences. Having better machines means you can think of a more efficient and at the same time a more economical design. Everything is related.

A current electronic circuit has nothing to do with one of 10 years ago, for example. To give you an idea, currently, in a measuring instrument the firmware inside the processor is one of the most important parts of the entire product when a few years ago it did not exist. It was gaining importance and now it is relevant.

In 1988 the company began its international expansion. This fact represented some changes in the way of working for R&D in Tecfluid?

EC – Yes. The first thing you have to do when you open to the world is to try to understand the needs of each market and adapt to them.

In our case, this involved from certifying equipment under the regulations of other countries to adapt the products dimensionally to the needs of each one, to the different regulations, etc…

IECEx certification for our DP, SC250 and LP series

at international level

TR CU certification for our products

in Russia, Belarus and Kazakhstan

Do you work closely with other departments of the company? Which ones and why?

EC – Yes, we are not only an R&D department but also an engineering department. This means that we adapt the design to the manufacturing methods that we have available, and for that, we must work hand in hand with the manufacturing departments. We always have direct contact with the Management of the company, since it is who gives us the approval to start with a design project, but we also work very closely with the sales department so that the designed product meets the conditions required by the market.

How R&D in Tecfluid determine the development of new products?

EC – We take into account three aspects: the needs of the market, the evolution of the competition or also an internal need. The needs of new products are established from meetings with the sales department and the management. Many times, we also value the need to manufacture a customized product for a specific customer, no longer for a general market but for specific cases. Moreover, you always have to see how the competitors evolve, in order to keep up with them or even better.

And what is the overall process of that product development?

EC – The communication between departments is very important. We have regular meetings within the R&D department itself and with the sales, manufacturing and quality departments. In this way, the product is validated as the design process progresses and thus verify that there is no incompatibility. When a design is finished, the parties involved in its manufacture and sale know in advance how that product is and what its characteristics are.

FLOMID electromagnetic flowmeter + XL1 converter

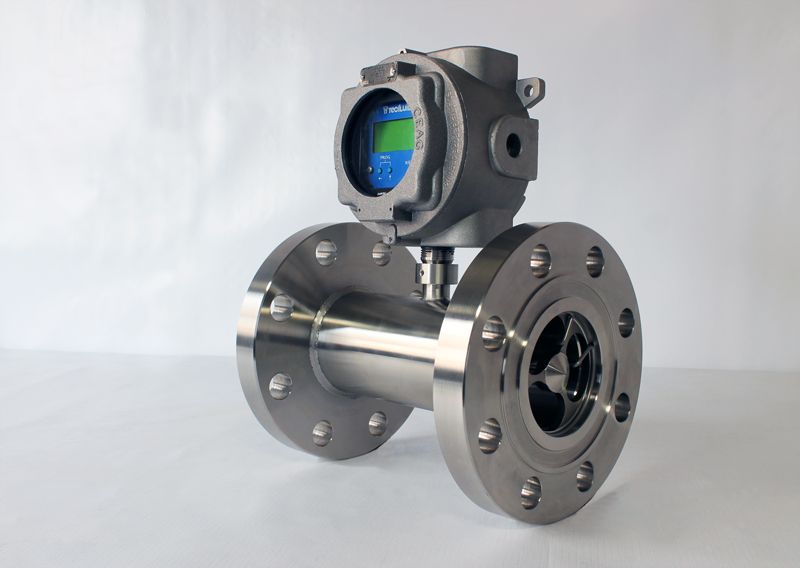

Turbine type flowmeter with ANSI 300# flange and ”

Large Groove”, Exd housing with display and special length

What challenges do you usually face?

EC – One of the most important is to design products that fit the market, but not only at the functional level, but also at the cost level. We must constantly evaluate that the costs of the product we are designing do not exceed expectations and end up being a product not accepted by the market, although it works very well.

Which has been the instrument that has represented a major challenge to date or greater success? Why?

EC – I think the ultrasonic flowmeter because of its complexity. We are in the process of developing a new version of this product in which there are great advances compared to the current one. We have invested a lot of knowledge in contact with the Universidad Politecnica de Cataluña (UPC), through an industrial doctorate from one of our engineers. On the other hand, at a technology level, we are using last-generation devices that greatly improve the measurement process.

In terms of success, the products with a higher sales volume are “classic” products, some purely mechanical such as variable area flowmeters, and which we have been selling practically since our beginnings. To talk about success maybe I, as head of the department, would say that the electromagnetic flowmeter with all the inline and insertion variants that have been developing since I joined Tecfluid. Aspects as the updating of the existing product at that time, incorporation of the microprocessor for the first time, incorporation of the digital signal processor (DSP) later on, the different electronic converters applicable to this type of flowmeters, and now a new battery-powered version that will be shortly launched to the market.

“One of the most important challenges is to design products that fit the market, but not only at the functional level, but also at the cost level. We must constantly evaluate that the costs of the product we are designing do not exceed expectations and end up being a product not accepted by the market, although it works very well”

In Tecfluid we also adapt standard equipment for specific customer applications … how is this matter managed?

EC – From a customer’s need, the sales department generates a design request, which is evaluated by the Management and by the R&D in Tecfluid. Depending on several factors, it is decided if it is feasible to carry out the design that covers that customer’s need. One factor could be the possibility to manufacture the product not only mechanically but also with regard to the timing of the customer and other projects in which we are working at that moment. Also, it depends on the number of units to be manufactured to see if it is sufficient for the costs and the benefit will be reasonable for the customer and our company … The development process begins when everything is linked.

Product development: Design, prototype, production and final piece

And are there many differences in the development of flow and level measurement system? What about between the different flow measurement systems, for example?

EC – Flow and level are two different worlds. The only thing they have in common are the signals that give information to the user regarding the measurement made by the instrument.

Among the flowmeters, we could say that the most different part is the principle of measurement. If we compare a variable area flowmeter with an electromagnetic flowmeter, their sensors are completely different. The design of the sensor is the part of the equipment that is responsible for converting a physical signal into a usually electronic signal and each way of measuring the flow rate is what makes the difference.

Once you have an electrical signal from the sensor, it is sent to the converter processor unit that performs the processing and it converts it into a useful and treatable signal. From here it is where there are more similarities between all of them.

On the other hand, the design of the converter, which converts the sensor signals into useful signals to be interpreted, is more common for the different types of flowmeters, although there are also small differences.

The same applies to the different measurement principles of level measurement instruments.

Do you consider that the certifications of the equipment are an important point for the sale of the instruments that you develop?

EC – Yes, totally. In addition, these certifications could be divided into two types: Compulsory and voluntary certifications.

Nowadays a manufacturer of flow and level measurement equipment is obliged to comply with certain directives, and these directives entail following a series of standards. Many are fulfilled via certifications from external notified bodies, e.g. the Pressure Directive. Some of the equipment we manufacture must be compulsorily subjected to the Pressure Directive and must comply with it, and this means that they must be certified.

On the other hand, there are voluntary certifications. We have equipment that can be installed in explosive atmospheres and this field is contemplated by a European directive and by world organizations, e.g. the IECEx international certification system. We say that it is voluntary because our company could decide not to manufacture equipment for explosive atmospheres, but we are interested because they are equipment that our clients require and therefore they are part of our business.

Therefore, certifications are very important. In Tecfluid we have Certificates of Quality, Low Voltage, Electromagnetic Compatibility, etc … with respect to the equipment that we manufacture. Being under the ISO9001 Regulation involves all of this.

In addition, there are different special certifications depending on the different countries of the world, such as Russia. We have to certify the equipment according to them in order to be able to market them in those countries.

In what projects is the department involved at this time?

EC – Now we are working to finalize the new version of the ultrasonic flowmeter and, as an important project, in the development of a new flowmeter with a measurement system different from all of those available: the calorimetric, designed for air or gases.

In the level range, we have already completed the process of certification of a product for use in explosive atmospheres and we are only waiting for receiving the certificate.

Prototype of our next CTR120 calorimetric flowmeter

What role do you think the R&D department represents in Tecfluid?

EC – I think it is very important since R&D is where the heart of all the products comes from. Having this department represents for the company a total knowledge of the product that not all companies have. Most companies depend on an R&D external department or subcontracted many times, and when there are incidents or possibility of improvements in their products, they do not depend on themselves. In our case, this is an important added value that allows us to provide high-quality after-sales service and adapt equipment to the customer’s needs.

Do you think Tecfluid’s product range also reflects the technological evolution of the sector in recent years?

EC – Yes. Especially, in electronics. Nothing to do a current product with one from 10 years ago. Nowadays, one of the most important parts of an instrument is the firmware that the processor incorporates. In the mechanical part, practically all our equipment has been updated as well since we began to manufacture them.

Do you consider that R&D in Tecfluid has evolved at the same pace as other departments of companies in the sector?

EC – Yes, I think we have evolved at a good pace within the possibilities of the company. Make a comparison between an R&D department of a family business, as is ours, and a large multinational company perhaps is not applicable.

What do you think is the future of the department in the medium and long term?

EC – What I think is clear is that the department has to continue to be one of the cores for the company. Logically, as head of R&D in Tecfluid, I would like to have more means, at both personnel and material level, to carry out the processes more quickly and more efficiently. Nevertheless, it always depends on the intentions of the management of the company; I cannot say today what the long-term future of the department will be.

Tell us any anecdote of these years, just to finish

EC – It comes to my mind how bad we have made it happen sometimes to the calibration department.

When we do tests in this department, it is normal to get their help for the installation, commissioning, and operation of the flow rig, which has a multitude of pumps, valves, etc….

Sometimes it has happened to us that by not bothering or wanting to go faster, we have “had a shower” with our clothes on or turned the facilities into a pool.

I remember especially once when a laptop got completely wet, it jumped through the air and the good thing is that it recovered and it still works!

Thanks Esteve 🙂 , you have really given us a new point of view of the work that is done in the R&D within a company.

Therefore, if you are interested in learning more about how this department works in Tecfluid, here you have this article with video included about how a component of a flowmeter is developed.